- No. 2 Street 623D, Phuoc Long B Ward, Thu Duc City, HCMC, Vietnam

- Admin@CTCinternimex.com

Exporting【Dried Rubberwood Lumber】at the best prices | Worldwide shipping

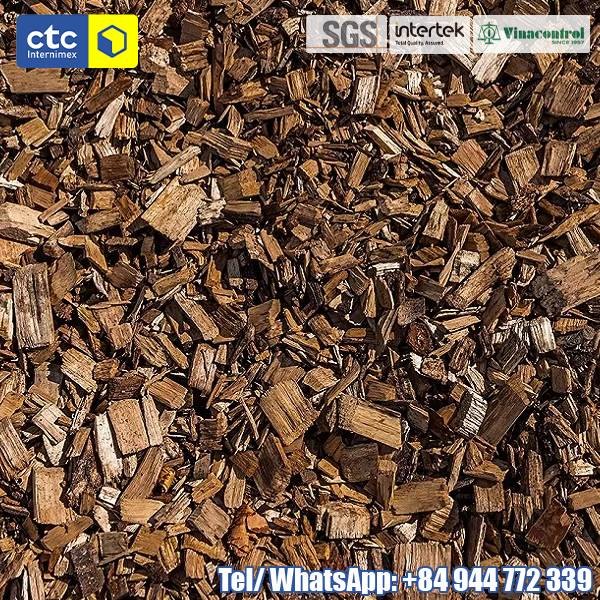

Wood Chips

Product code: UpdatingPRICE CONTACT

- Best price in Vietnam

- Certificate of Origin (CO form of FTA): Vietnam

- Specifications: Customized

- Product model: OEM, ODM

- Third party inspection: SGS, Intertek, Vinacontrol

- Flexible payment terms: TT or L/C

- Delivery terms: Incoterms 2020 (FOB, CIF,...)

Quantity

1

PRODUCT DETAILS

Key attributes

Industry-specific attributes

| After-sale Service | Online technical support |

| Application | Particle board, pulp,... |

Other properties

| Place of Origin | VIETNAM |

| Brand name | CTC internimex JSC |

| Product name | Wood Chips |

| Port | Cat Lai Vietnam |

| Material | Pine, Acacia, Eucalyptus, Rubber Wood, Etc. |

| Color | Natural wood color |

| Humidity | Customized |

| Size | 2-10mm |

| Packing | According to customer's requirement |

| MOQ | 1 Container 20ft |

| Delivery | 10-20 days |

GENERAL INTRODUCTION

Wood Chips: "Small But Mighty" Material in the Wood Industry

Wood chips, despite being just tiny fragments, play a significant role in the wood industry. So, what are the characteristics of wood chips? What are their applications? Let's find out in detail in this article.

Introduction to Wood Chips

Wood chips are a byproduct of wood processing, created from grinding, cutting, and chipping natural wood. They are small in size, with irregular shapes, often in the form of flakes, fibers, or chips.

Outstanding Advantages

- Low cost: Wood chips are a byproduct, utilizing leftover wood resources, resulting in a low cost.

- Abundant supply: Large production of wood chips meets various usage demands.

- Environmentally friendly: Utilizing wood waste helps reduce waste and protect forests.

Disadvantages to Note

- Inconsistent quality: The size and shape of wood chips are not uniform, which can affect the quality of the final product.

- Susceptible to moisture and mold: Requires careful storage in a dry, well-ventilated environment.

Notable Features

- Compact size: Easy to transport and store.

- High applicability: Widely used in many fields.

Wood Chip Manufacturing Process

- Raw material collection: Utilizing wood scraps, branches, wood ends... from wood processing factories.

- Grinding, cutting, chipping: Using specialized machinery to create wood chips of appropriate sizes.

- Screening: Removing impurities, classifying wood chips by size.

- Storage: Storing wood chips in a dry, well-ventilated warehouse.

Diverse Applications

- Production of particle board: The main raw material for producing particle board (Okal board), MDF, HDF,...

- Production of wood pellets: Compressing wood chips into pellets used as biomass fuel.

- Agriculture: Used as bedding material, soil cover,...

- Decoration: Used in handicraft products.

Classification of Wood Chips

- Based on size: Small wood chips, medium wood chips, large wood chips.

- Based on wood type: Pine wood chips, rubberwood chips, mixed wood chips,…

Conclusion

Despite being a byproduct, wood chips still have high economic value and contribute positively to the sustainable development of the wood industry.

Contact us for more information and pricing on Wood Chips.

Comment

Comment and review